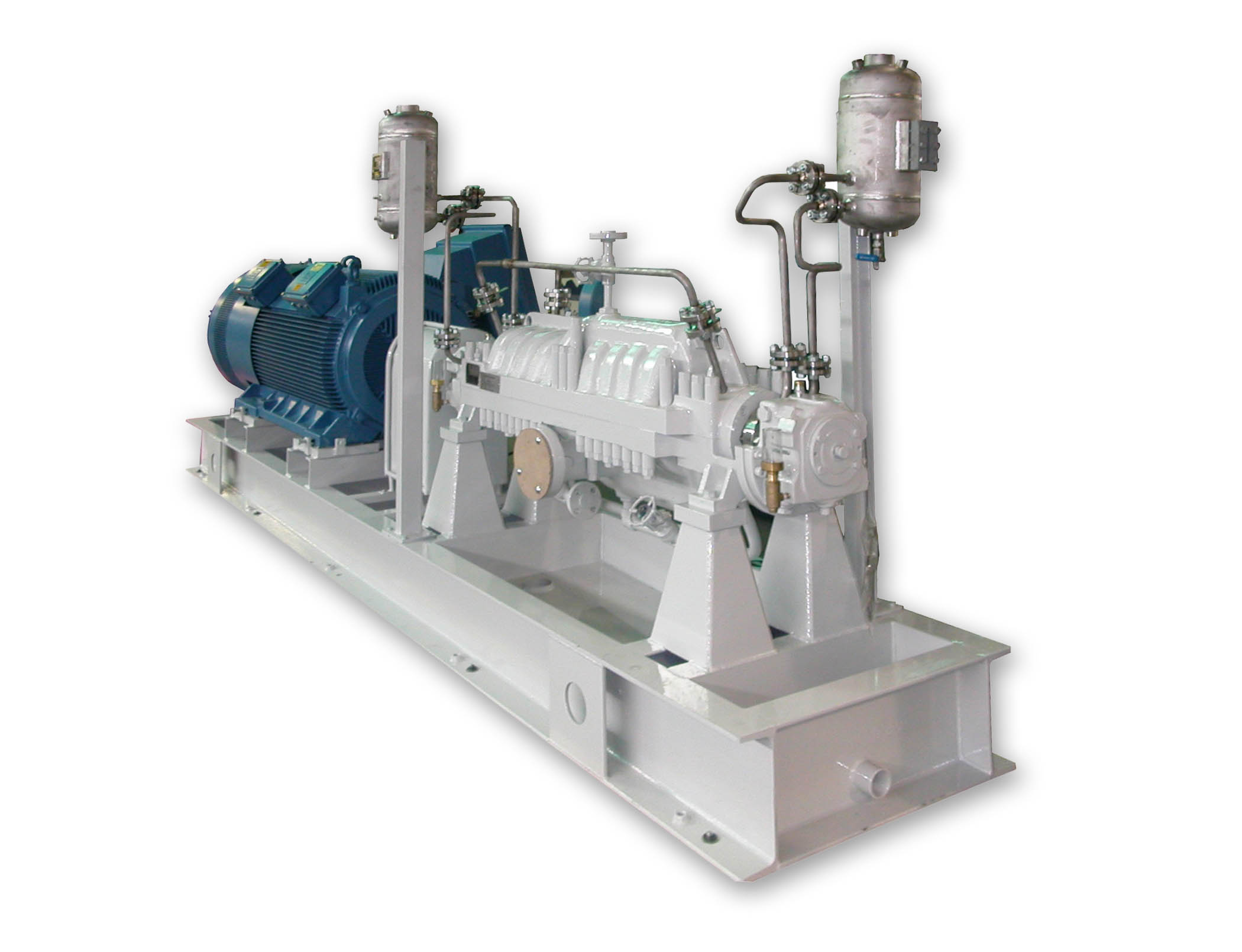

Designed for processes engineers requiring reliable operation in the full range of high pressure services

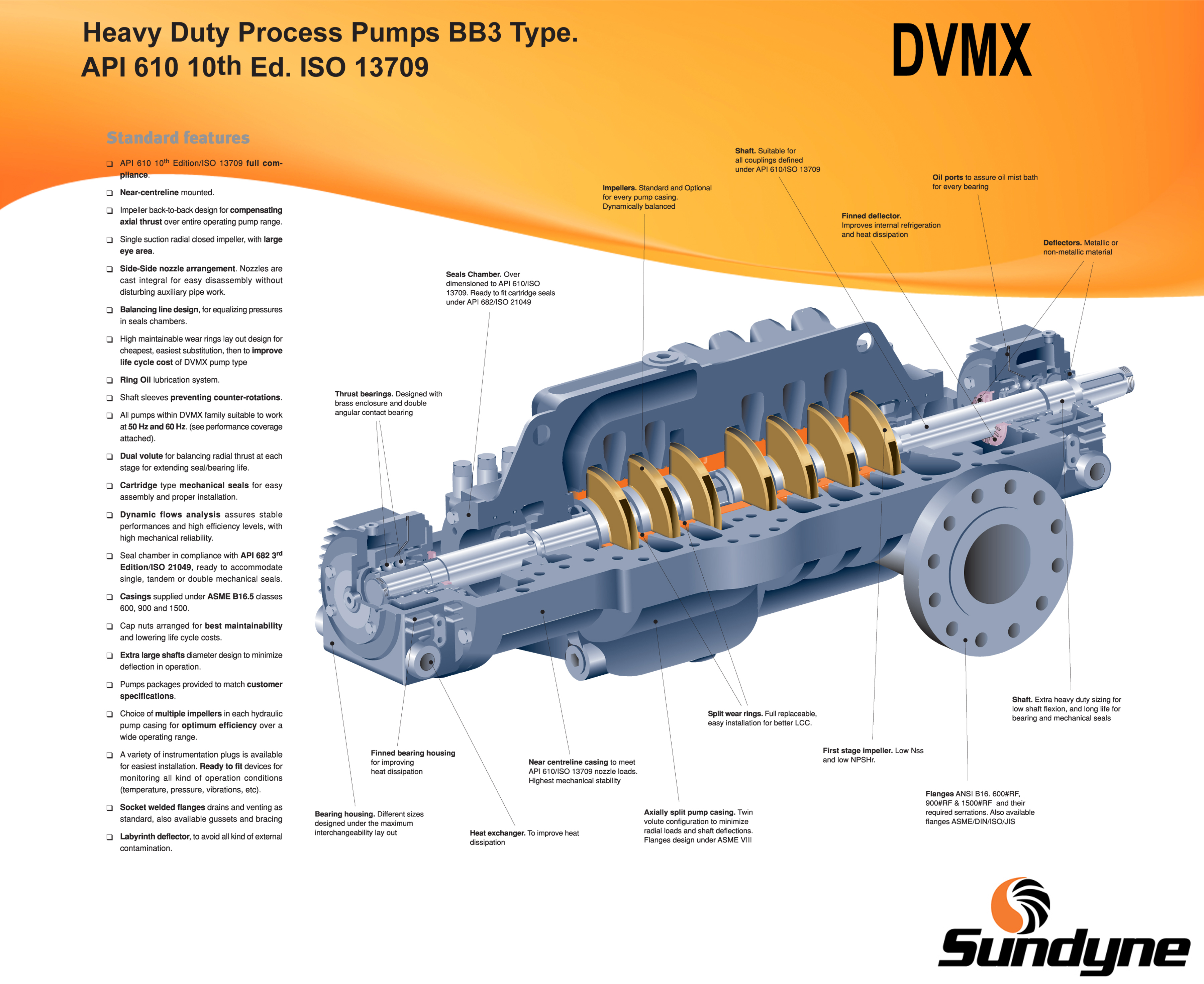

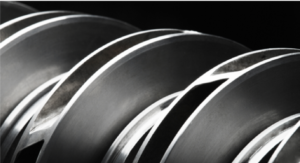

The DVMX fully compliant API-610 11th Edition BB3 and ISO 13709 multi-stage process pump. Available in 4 – 14 stages. Horizontal axial split case running back to back impellers in heavy-duty double volute casings.

- Flows to 2,640 gpm (600 m³/hr)

- Heads to 4,260 ft (1,300 m)

- Suction Pressure 232 psi (16 bar)

- Temperature Range -40 to 410°F (-40 to 210°C)

Precision engineered API/ISO 13709 process pumps meeting rigorous engineering requirements for heavy duty, high temperature applications while receding the total life cycle cost and improving mean time between repairs. A perfect high-flow, high-head compliment to Sundyne low-flow, high-head integrally geared LMV and BMP centrifugal pumps.

APPLICATIONS

- Boiler feed water

- High pressure water services

- Crude oil pipeline

- Crude products pipeline

- Water injection

- High pressure condensate

- Propane transfer

- Gasoline pipeline service

- NGL pipeline

- Mine dewatering

- Water flood

- HP amine circulation

- High pressure refinery services

- Process charge

- De-scaling

- CO2 injection

Proven to be reliable, efficient and long-lasting, Marelli BB3 pumps provide a number of operational benefits for process engineers and plant operators:

- API 610 11th Edition/ISO 13709 full compliance for reliability and accountability

- Suitable with 60 Hz and 50 kW motors

- Near-centerline mounted pump casing maintains alignment during operation at elevated temperatures

- Opposed impeller design for balanced axial thrust for optimal seal and bearing life

- Single suction closed impeller, with large suction eye for low NPSH requirements

- Side-side nozzle arrangement. Nozzles are cast integrally with lower casing half for easy disassembly without disturbing auxiliary pipe work

- Balancing line design for equalizing pressures in seal chambers for optimal seal life

- Highly maintianable and easily replaceable wear rings to reduce overall life cycle costs

- Ring oil lubrication system that incorporates a constant level oiler and sight glass

- Dual volute for balancing radial thrust at each stage and for optimizing seal and bearing life

- Cartridge type mechanical seals for easy assemble and proper installation

- Dynamic flows analysis assures stable performance and high efficiency levels, with high mechanical reliability

- Seal chamber in compliance with API 682 3rd Edition and ISO 21049, ready to accommodate single, tandem or double mechanical seals

- Casings supplied under ASME B16.5 class 600, 900 and 1500

- Cap nuts are arranged on the top half casing parting flange, allowing easy casing removal for rotor inspection and ease of maintenance

- Extra large shaft diameter design to minimize deflection in operation

- Choice of multiple impellers in each hydraulic pump casing for optimum efficiency over a wide operating range

- A variety of instrumentation options are available for monitoring all key operating parameters (temperature, pressure, vibrations and more)

- Socket welded, flanged drains and vents as standard (Gussets and bracing are available)

- Labyrinth bearing seals, deflector, to avoid external contamination and maximizing seal and lubrication life

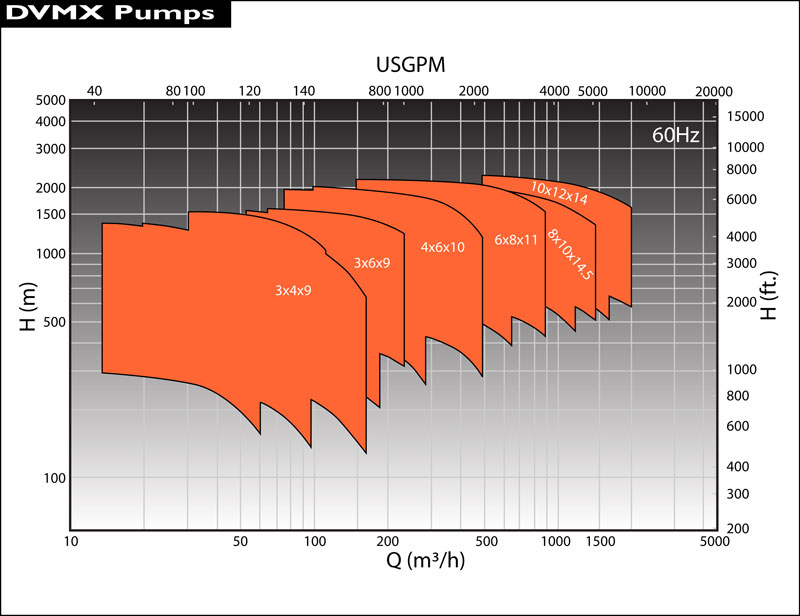

US 60 Hz

- Heads to 4,260 ft

- Flows to 2,640 gpm

- Standards API 610 OH2

- Maximum Motor Power 2500 HP

- Temperature Range -40 to 410°F

- Maximum Case Working Pressure 1,740 psi

- Maximum Suction Pressure 232 psi

- Differential Head 3,937 ft

- Maximum Viscosity Consult Factory

- Mounting Configuration Horizontal-Side-Side

- Seal Configurations API 682

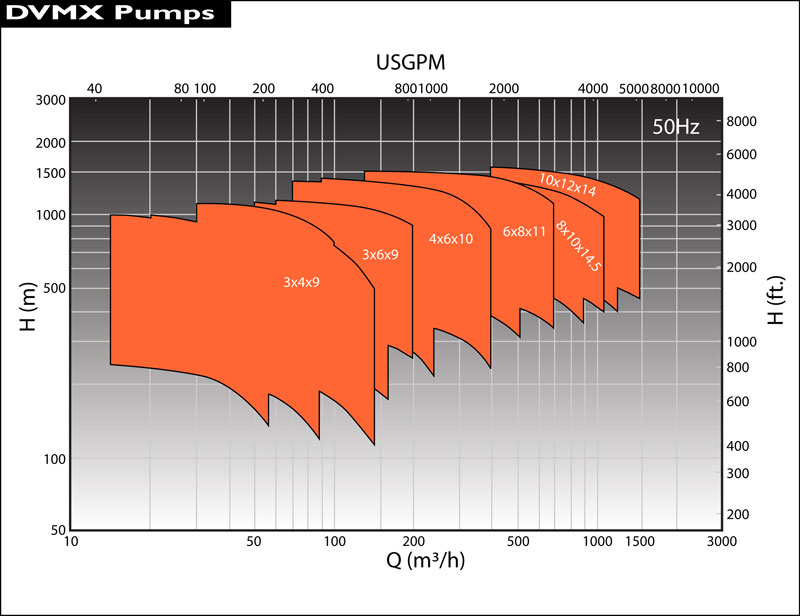

Metric 50 Hz

- Heads to 1,300 m

- Flows to 600 m3/hr

- Standards ISO 13709

- Maximum Motor Power 2,000 kW

- Temperature Range -40 to 210°C

- Maximum Case Working Pressure 120 bar

- Maximum Suction Pressure 16 bar

- Differential Head 1,200 m

- Maximum Viscosity Consult factory

- Mounting Configuration Horizontal-Side-Side

- Seal Configurations API 682

| Part | S1 | S5 | S6 | S8 | C6 | A8 | D1 |

| Pressure Casing | Carbon Steel (A216 WCB) | 12% CHR | 316 AUS | Duplex | |||

| Impeller | Cast Iron | Carbon Steel | 12% CHR | 316 AUS | 12% CHR | 316 AUS | Duplex |

| Wear Rings | Cast Iron | 12% CHR Hardened | Hard-faced 316 AUS | 12% CHR Hardened | Hard-faced 316 AUS | Hard-faced Duplex | |

| Shaft | Carbon Steel | AISI 4140 | 316 AUS | 12% CHR | 316 AUS | Duplex | |

| Bearing Housing | Carbon Steel (A216 WCB) | ||||||

| Base Gasket | AUS, Spiral Wound | 316 AUS Spiral Wound | AUS, Spiral Wound | 316 AUS, Spiral Wound | Duplex SS Spiral Wound | ||